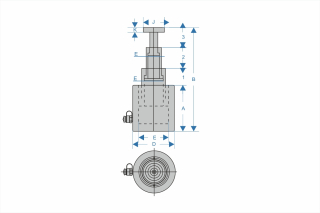

For use where there is a minimum clearance for the insertion of cylinder and a very high lift is necessary. Single acting, load return. High strength alloy steel for durability. Chrome plated piston resists wear and corrosion. Baked enamel finish for increased corrosion resistance. Each cylinder has an GR-II 3/8" NPT male half coupler and dust cap. Each cylinder has a flat grooved saddle.

Working pressure: 700bar.

| Code | Model | Cylinder capacity |

Stroke mm |

Stroke mm |

ffective area sm² |

Oil capacity sm² |

Closed height mm |

Ø оutside mm |

Øinside mm |

Ø standard saddle | Saddle protr. from plgr. | Gross weight kg |

Handle | Recommended pump | ||

| Ton | Stage | KN | A | D | E | J | K | |||||||||

| 22501084 | GRYG-10270D | 10 | 2 | 111 | 135 | 270 | 15,9 | 810 | 250 | 110 | 45 | 48 | 19 | 18 | Eye bolts |

GRB-700A |

| 1 | 309 | 44,2 | 75 | |||||||||||||

| 22501085 | GRYG-10435D | 3 | 111 | 145 | 435 | 15,9 | 2250 | 208 | 153 | 45 | 78 | 40 | ||||

| 2 | 309 | 44,2 | 75 | |||||||||||||

| 1 | 665 | 95 | 110 | |||||||||||||

| 22501086 | GRYG-15300D | 15 | 2 | 166 | 150 | 300 | 23,7 | 1308 | 208 | 125 | 55 | 63 | 28 | |||

| 1 | 445 | 63,6 | 90 | |||||||||||||

| 22501087 | GRYG-15510D | 3 | 166 | 170 | 510 | 23,7 | 3543 | 320 | 175 | 55 | 112 | 60 | GRB-630A | |||

| 2 | 445 | 63,6 | 90 | |||||||||||||

| 1 | 1002 | 143,1 | 135 | |||||||||||||

| 22501088 | GRYG-30300D | 30 | 2 | 309 | 150 | 300 | 44,2 | 2088 | 304 | 152 | 75 | 85 | 23 | 45 | GRB-700A | |

| 1 | 665 | 95 | 110 | |||||||||||||

| 22501089 | GRYG-30600D | 3 | 309 | 200 | 600 | 44,2 | 6803 | 366 | 220 | 75 | 142 | 106 | GRB-630A | |||

| 2 | 665 | 95 | 110 | |||||||||||||

| 1 | 1496 | 213,7 | 165 | |||||||||||||

| 22501090 | GRYG-50300D | 50 | 2 | 496 | 150 | 300 | 70,8 | 3800 | 350 | 170 | 95 | 105 | 29 | 68 | ||

| 1 | 1002 | 143,1 | 135 | |||||||||||||

| 22501091 | GRYG-50600D | 3 | 496 | 200 | 600 | 70,8 | 9500 | 390 | 230 | 95 | 160 | 152 | ||||

| 2 | 1002 | 143,1 | 135 | |||||||||||||

| 1 | 1984 | 283,4 | 190 | |||||||||||||

See pages 161-164 recommended pump hydraulic pumps